Time:2024-07-08 Preview:241

PCB Assembly Capabilities

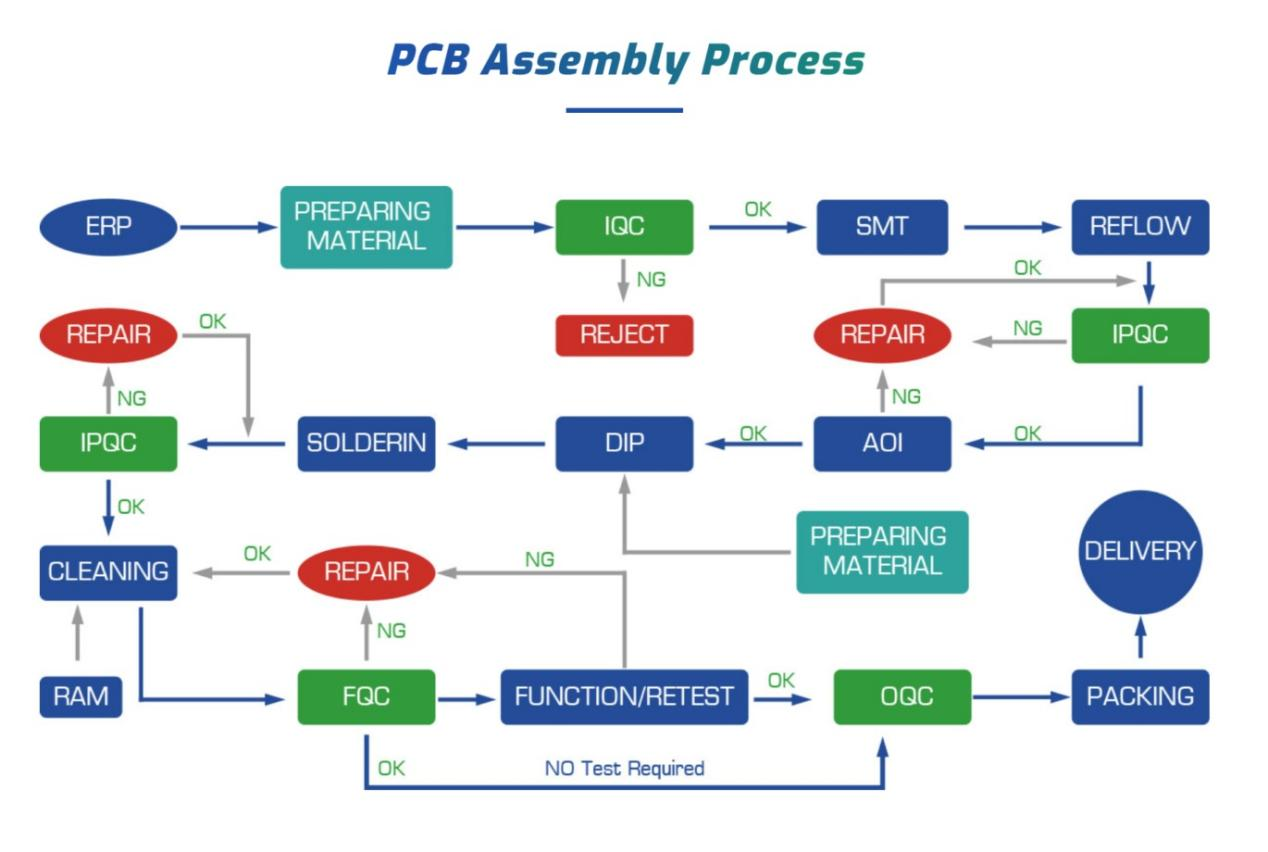

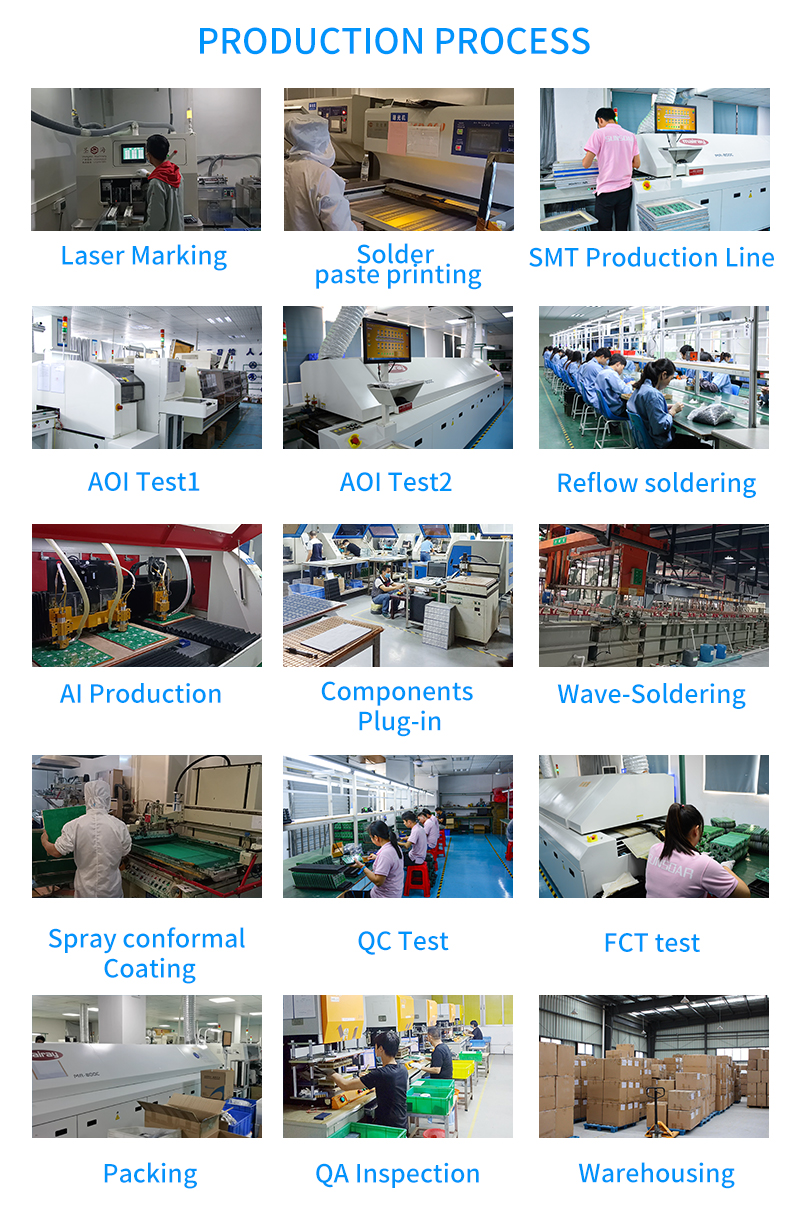

PCB ASSEMBLY MANUFACTURING PROCESS

PCB ASSEMBLY MACHINE

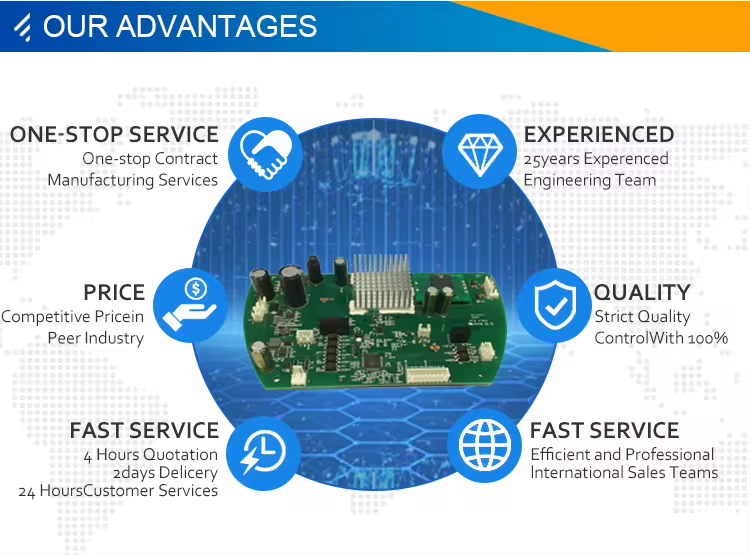

THE ADVANTAGES OF OUR FACTORY

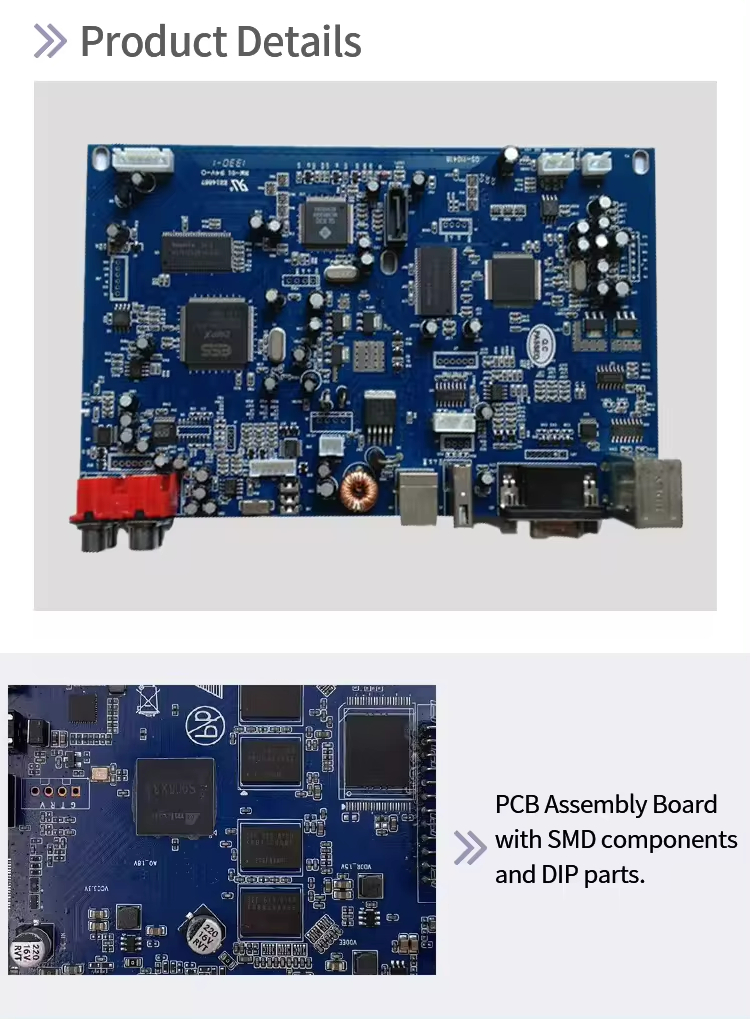

SURFACE MOUNTING OF PRINTED CIRCUIT BOARDS (SMD MOUNTING)

FAST TURNAROUND/QUICK TURN PCB ASSEMBLY MANUFACTURING COST

TYPES OF PCB ASSEMBLY

PRODUCTION PREPARATION INCLUDES THE FOLLOWING STEPS:

ASSEMBLY OF PRINTED CIRCUIT BOARDS FROM SPECIALISTS

AUTOMATIC PCB ASSEMBLY

QUALITY CONTROL OF PCB ASSEMBLY

PCB Assembly Capabilities | ||

Features | Economic PCBA | Standard PCBA |

Assembly Types | Single sided placement | Single & double sided placement (SMT/Thru-hole) |

PCB Layer | 2,4,6 layers | 1 - 20 layers |

Thickness | 0.8mm - 1.6mm | 0.4mm - 2.0mm |

Dimension | Single PCB Size: | Single PCB Size: |

10x10mm - 570x470mm | 70x70mm - 510x460mm | |

PCB Panel Size: | PCB Panel Size: | |

10x10mm - 250x250mm | 70x70mm - 250x250mm | |

Order Volume | 2 - 50 pcs | 2 - 80000 pcs |

Surface Finish | Limited by specific options | No limit |

(Refer to the options for Economic PCBA in the table below) | ||

PCB Color | Limited by specific options | No limit |

(Refer to the options for Economic PCBA in the table below) | ||

Delivery Format | Single PCB, Panel with mouse bites | Single PCB, Panel with mouse bites, Panel with V-cut |

Layer Stackup | Standard stack-up only, | All stack-up |

Gold Fingers/Castellated Holes | Not Support | Support |

Edge Rails | Not necessary | Necessary |

Fiducials | Not necessary | Necessary |

Minimum Package | 402 | 201 |

Minimum IC Pin Spacing | 0.4mm | 0.35mm |

Minimum BGA Spacing | 0.5mm(center to center) | 0.35mm(center to center) |

Reflow temperature | 255+/-5 °C (not adjustable) | 240+/-5 °C |

SPI | No | Yes |

AOI | Yes | Yes |

Visual Inspection | Yes | Yes |

X-ray Inspection | Yes | Yes |

Build time | 1 - 3 days | ≥ 4 days |

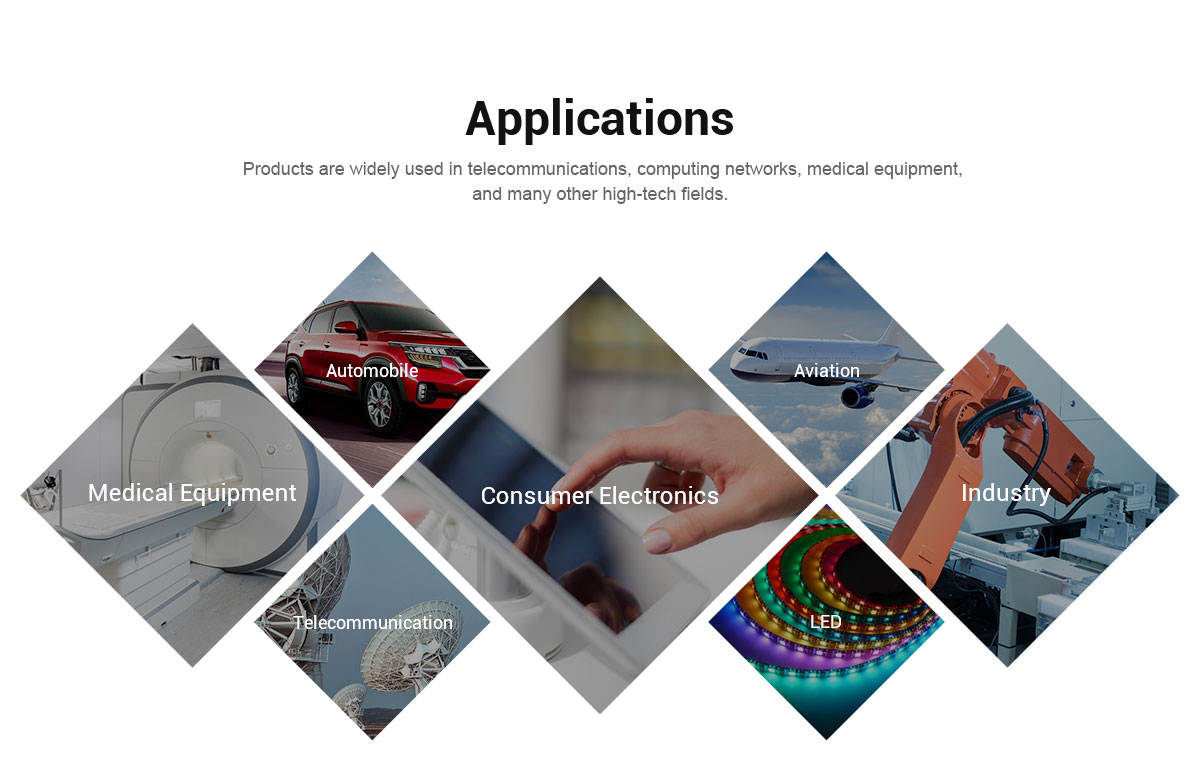

Our factory carries out the assembly and installation of printed circuit boards to order. During the development and manufacturing process, constant quality control is carried out.

We strictly follow your Gerber file and Bom list for your fast turnaround or quick turn PCBA projects, and we will also be glad to suggest you the alternative for your passive components to decrease your cost, but all replacement components need you to approve and make the final decision on whether you want to use them.

his manufacturing process will make PCB manufacturer control the quality of your orders well, and leads us to fulfill your fast turnaround (quick turn) PCB Assembly orders in time.

· Automatic SMT lines(Japan Yamaha) and DIP lines.

· Smaller packages 01005, and BGA can be 0.1mm.

· The capability of consumer electronics and industrial electronics.

· Best waterproof technology(coating and Parylene).

· Waterproof PCBA ———Parylene

· Nano-vacuum coating is to pyrolyze Parylene polymer materials into nano-molecules and then perform vacuum coating treatment on the surface of the product. Vacuum vapor deposition equipment (CVD) enables the coated object to have the following characteristics: waterproof, moisture-proof, acid and alkali resistance, and salt resistance Fog, high compression resistance, biocompatibility

· High reliability: suitable for military or commercial use, almost no gas release

· IPX-8 protection: long diving, soaking in water

· Ultra-thin coating: does not affect the product size(controllable 5-30um)

· Room temperature coating: the product to be coated is at room temperature, and the temperature range under a vacuum environment is wide: suitable for minus 200°C to 200°C.

· High transparency: film layer can reach Real integration of optical quality: the uniform thickness of various surfaces, high uniformity and stress-free surface circuit sensitivity not affected by the coating, and low friction coefficient, can be used as a dry film lubricating layer

· Biocompatibility: inert, especially suitable for medical applications

Specialists of our factory have many years of experience in assembling PCBs for various purposes. We guarantee:

EXECUTION OF THE ORDER JUST IN TIME.

We comply with the terms described in the contract. We provide fast delivery throughout the world.

In our factory, you get the most favorable conditions for services and the sale of goods.

We can do the programming and function test for your PCBA per your instruction.

PCB manufacturer can quote you the price very quickly, and it normally can be in one day, especially for the PCB Prototype.

We work only with reliable and professional material suppliers and component manufacturers/distributors.

We carry out contract fast turnaround assembly of printed circuit boards, as well as perform manual and automatic assembly of quick turn printed circuit boards of any complexity:

· surface mount technologies(SMD/SMT);

· output wiring (THT, DIP, volumetric);

· mixed installation.

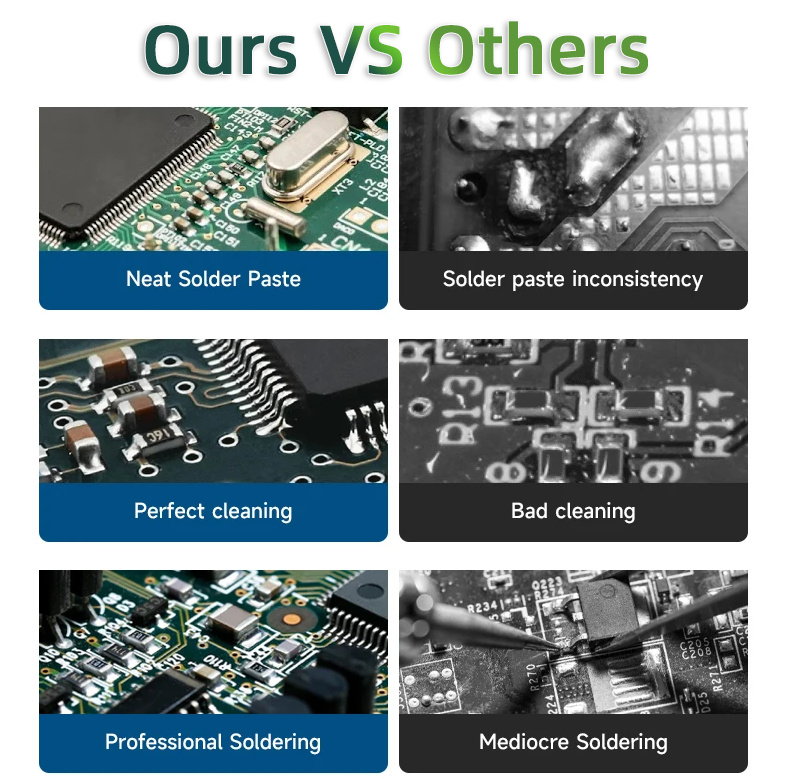

Modern equipment and a team of experienced specialists guarantee our clients favorable market conditions in terms of price-quality ratio. Each created board is tested by the Quality Department and is accompanied by a guarantee.

We carry out surface mounting of printed circuit boards (SMD) using premium equipment. We have at our disposal two automatic lines for surface mounting based on high-performance installers of SMD components for the fast turnaround/quick turn PCB Assembly.

This type of equipment provides high speeds of component mounting and is suitable for any type of package, including BGA and LGA. With this machine, PCB Manufacture can make fast turnaround/quick-turn PCB assembly orders in time.

Mixed PCB assembly is accomplished by a combination of surface and traditional through-hole output assembly technologies. This type of installation is the most common because modern printed circuit boards often contain both surface mount (SMD) and through-hole (THT, DIP) components.

Mixed assembly can be done in different ways for fast turnaround or quick turn PCB Assembly, depending on a number of factors and the purpose of the production. We can develop mixed assembly of printed circuit boards of any complexity.

The cost of assembling printed circuit boards is calculated individually for each order. The price depends on the number of ration points, the type of installation, the complexity of the printed circuit boards, the expected quantity, and the timing of the order. Our experts will calculate the exact cost of your project.

We apply various technologies for assembling printed circuit boards, relying on the experience and knowledge of the regulatory framework, depending on:

1. Used components and printed circuit boards in the device

2. Required types of installation

3. The unique requirements of the client for the technological process.

An automated mounting method allowing components to be placed in an SMD enclosure

The lead-out method of mounting components in DIP, SiP, ZiP, TO, and other packages is implemented using manual soldering technologies or on automated selective soldering plants.

The complex process of mounting printed circuit boards organizes an uninterrupted technological process for the production of electronic modules in which both surface and lead-out methods of fastening are used.

To provide high-quality assembly of printed circuit boards, the technologist requires careful attention to the documents received from the client, as well as to the choice of technological processes and tools for installation.

1. Detailed study of the received documentation from the client by technologists, clarification of details and client’s requirements for installation;

2. Making a stencil for uniform distribution of the solder paste over the seats;

3. Manufacturing of printed circuit boards (if necessary);

4. Supply of electronic components (if necessary);

5. Preparation of the thermal profile of the convection reflow oven and the selection of soldering materials depending on the applied project standards;

6. Preparation of production cycles and setting up an automatic installer for mounting printed circuit boards.

The company “KXPCB“ has competence in the field of installation of electronic modules.

We offer services for the installation of printed circuit boards on a turnkey basis with exact adherence to all customer specifications.

We have extensive experience working with clients in various industry areas.

WE PROVIDE:

· Compliance with international industry standards ( GOST, IPC )

· An integrated approach to work to ensure an accurate result

· Use only consumables accepted by international manufacturing companies

· Carrying out a technical audit of the product for launching into mass production

· Additional technical recommendations for the execution of electronic modules.

We provide our clients with high-quality work and professional service in compliance with all the necessary industry quality standards and individual technical conditions to finish your fast turnaround/quick turn PCB Assembly orders.

A high-speed or multi-function installer is used for automatic installation. Modern high-quality equipment specializes in automatic assembly. The technological equipment of the assembly production, which is responsible for this process, is aimed at solving various problems.

With the help of special attachments and tried-and-tested methods, complex components can be assembled.

The automated line of our enterprise has the technological capabilities for mounting packages from 0201 to microcircuits in packages with a small lead pitch and up to 54 mm in size of microcircuits in ball lead enclosures (BGA).

For high-volume production, a wave soldering machine can be used to solder the lead components. A high-performance line for the automatic assembly of printed circuit boards ensures the fulfillment of orders on time, regardless of the complexity and number of products.

Such installation is carried out for orders with a small number of products. Technological stages of manual assembly, installation of components, and soldering. The work of highly qualified specialists performing work with modern soldering equipment and using high-quality materials guarantees high-quality manual assembly of lead-out and surface-mounted components.

AREA FOR MANUAL ASSEMBLY OF PRINTED CIRCUIT BOARDS:

· manipulators, terminal forming devices,

· a high-precision installer for manual installation of enclosures and their rebelling.

Component installation costs are dependent on the amount of soldering in the order.

THE TOTAL COST DEPENDS ON:

· the number of boards of the same type in the order,

· the frequency of placing orders for installation

· number of board components

· cost of board components

As a professional PCBA manufacturer/ factory, and we pay special attention to quality control of the assembly of printed circuit boards at all stages of assembly and assembly work. All printed circuit boards are tested and guaranteed.

If you are looking for a Fast turnaround or Quick Turn PCB assembly Manufacturer, please send us an email now!