Time:2024-07-08 Preview:202

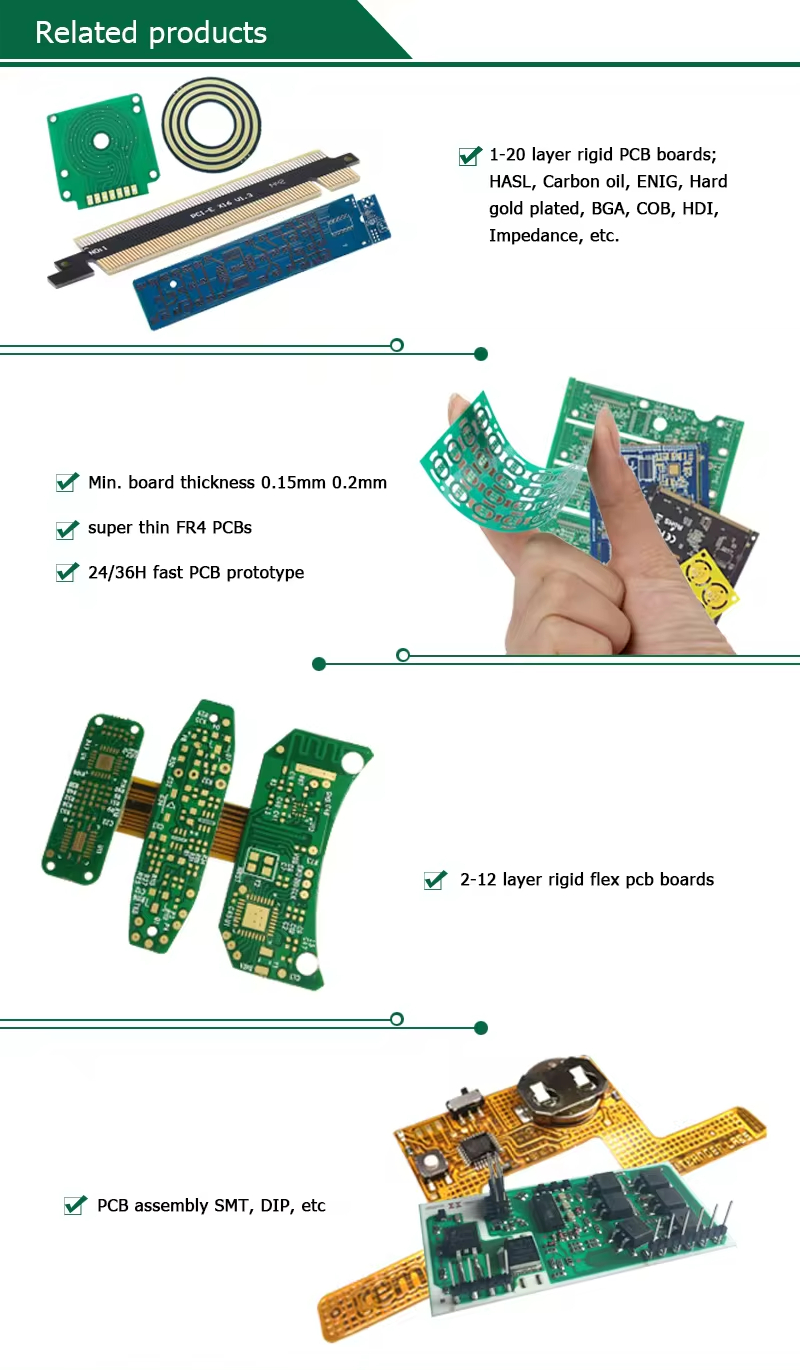

Rigid-Flex PCB manufacturing capabilities

What is a Rigid-Flex PCB

Rigid-Flex PCBs Fabrication Applications

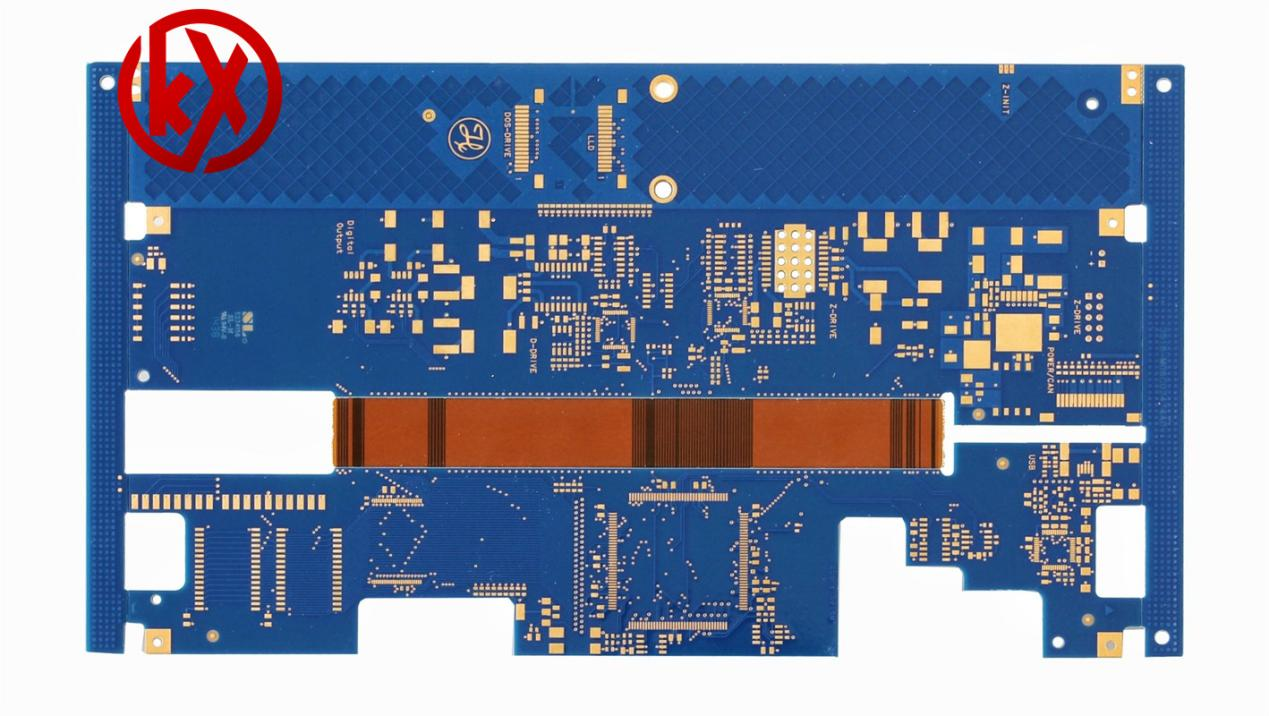

4 Layer rigid flex PCB

6 Layer rigid flex PCB

8 Layer rigid flex Circuit Boards

What advantages do our rigid-flexibe services provide ?

We carry years of rigid-flexible manufacturing experience.

Get well-defined rigid-flexible boards from us at best price.

Rigid-Flex PCB manufacturing capabilities :

Item | Capability |

Layers | 32 Layers |

Min Track / Spacing | 0.075 mm / 0.075 mm |

Min Hole Size / Pad Size | 0.10 mm / 0.35 mm |

Rigid-Flex Thickness | 0.25 mm-6.0 mm |

Max Copper Thickness | 5 oz |

Max WPNL Size | 610 mm X 914 mm |

Finish Copper(Flex Part) | 0.5-2 oz |

Finish Copper(Rigid Part) | 1-5oz |

Max Aspect Ratio | 13:1 |

Surface Finish | ENIG、Electric gold、IM-Ag、Electric Ag、HASL、 HASL-LF、IM-Sn、Electric Sn、OSP、Caborn、 PtNI-Pd-AU |

Drilling Accuracy | +/-0.05 mm |

PTH Diameter Tolerance | +/-0.05 mm |

Build time | 7-20 days |

RFQ | 1-2 days |

Layers | 32 Layers |

What is a Rigid-Flex PCB

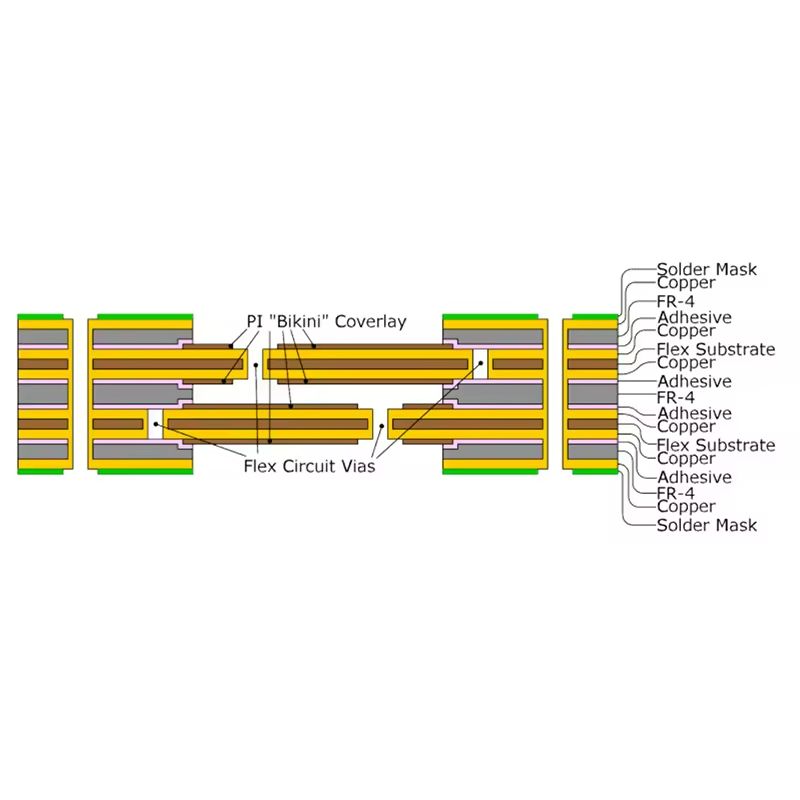

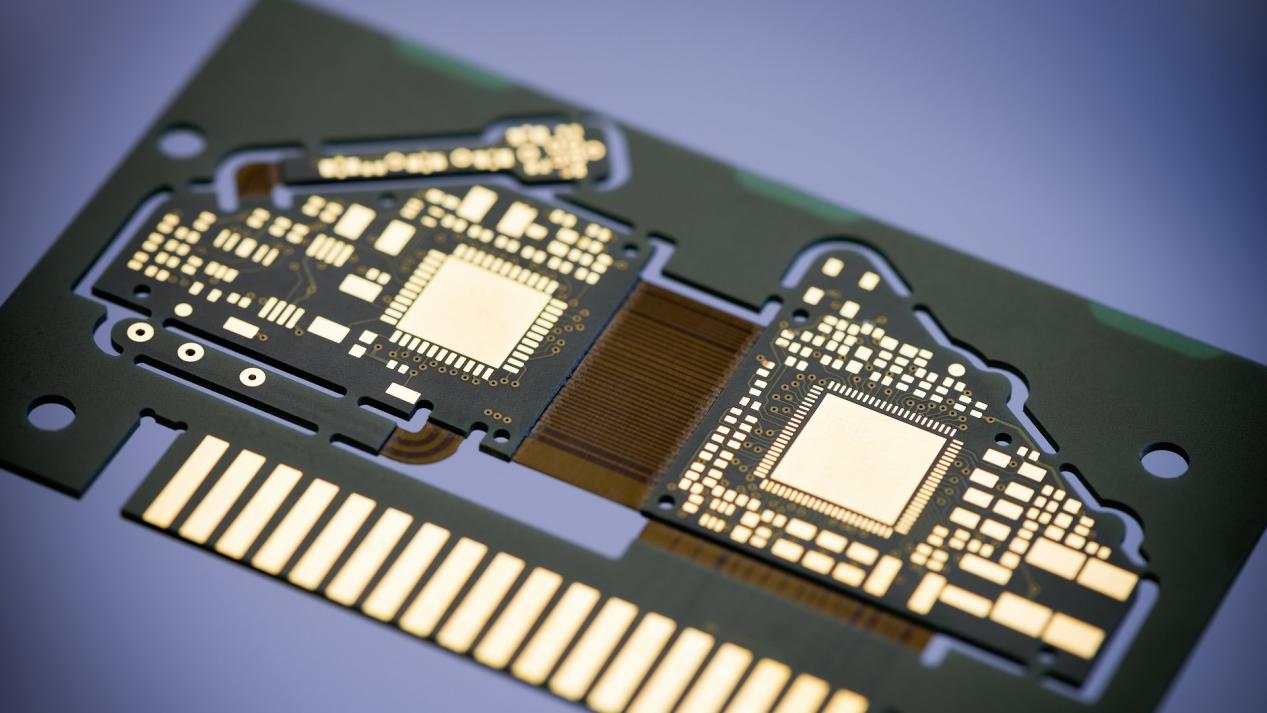

Rigid-Flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application. Most rigid flex boards consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application. The flexible substrates are designed to be in a constant state of flex and are usually formed into the flexed curve during manufacturing or installation.

Rigid-Flex designs are more challenging than the design of a typical rigid board environment, as these boards are designed in a 3D space, which also offers greater spatial efficiency. By being able to design in three dimensions rigid flex designers can twist, fold and roll the flexible board substrates to achieve their desired shape for the final application's package.

Rigid-Flex PCBs Fabrication Applications

Sphere | Types of Devices |

Automotive | Transport control systems. |

Computer Technologies | Video cards. |

Military and Space Industry | Radars. |

Telecommunications | Smartphones, tablets. |

The Medicine | Defibrillators. |

Heavy Weaponry | Electronic protection. |

Rigid-flex PCBs are mainly used to connect different parts of electronic devices.

4 Layer rigid flex PCB

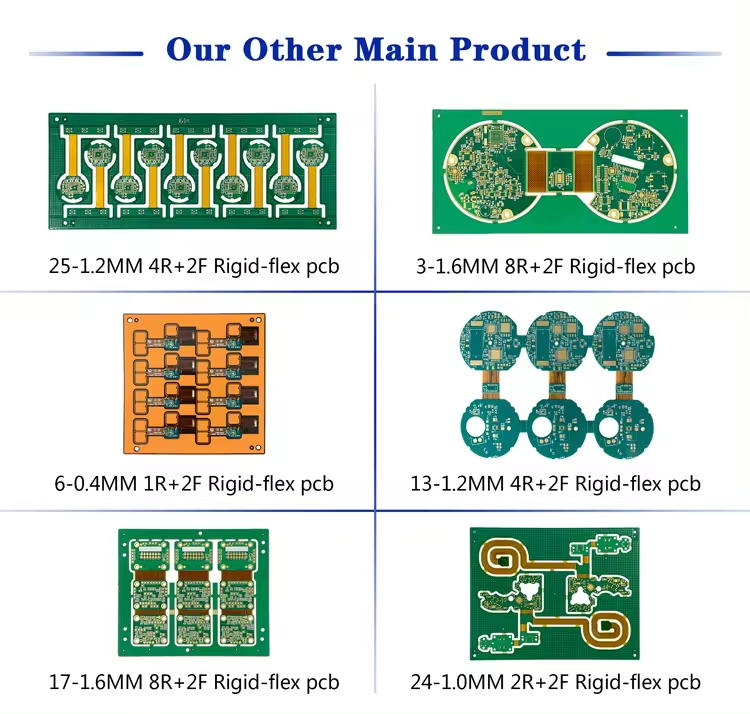

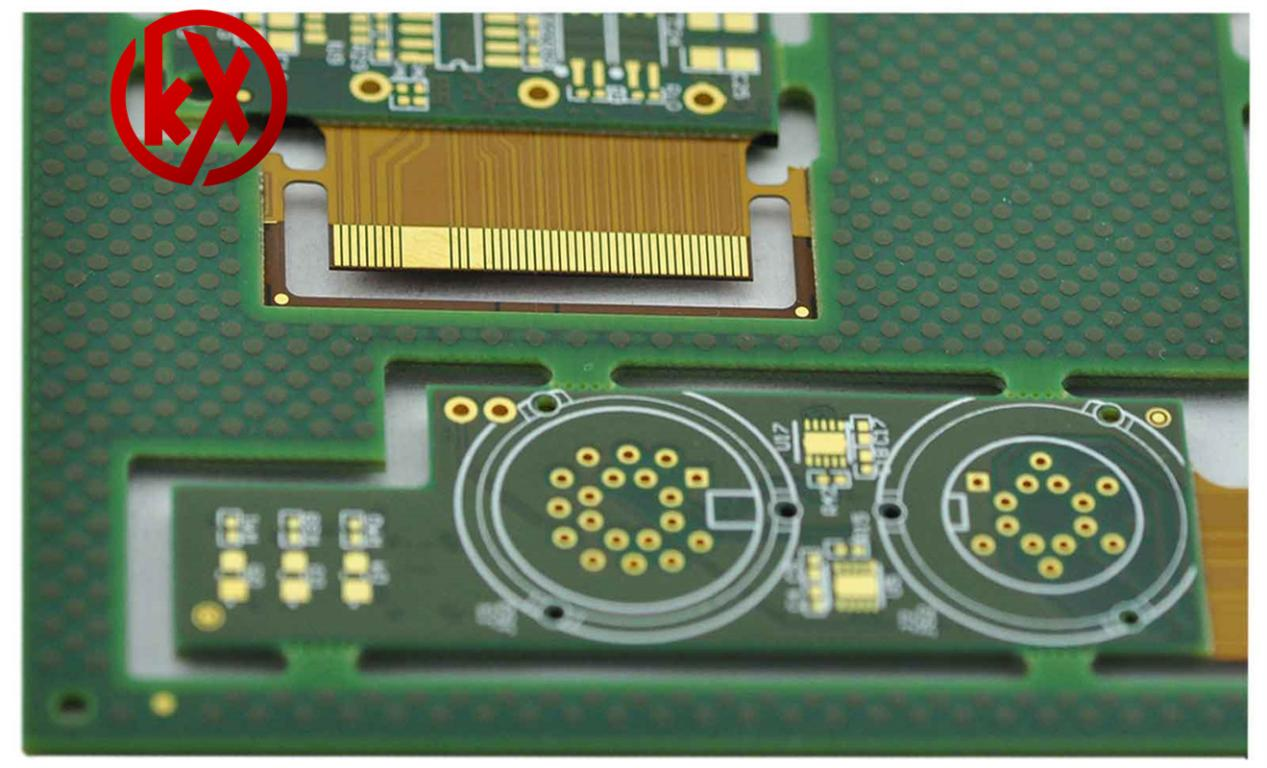

4 Layer rigid flex PCBBeing the leading rigid flex printed circuit board manufacturer, KXPCBprovides them in different custom sizes and surface finishes. This 4-layer rigid flex PCB with ENIG finish is ideal for applications that involve ball grid arrays, as well as surface mount devices. The basic material used for its construction includes polyimide, as well as FR4. The polyimide helps improve the temperature resistance of this circuit board and makes it ideal for high temperature applications.

ENIG is an abbreviation of Electroless Nickel Immersion Gold. It is basically a two layer coating of 2-8 μin Au over 120-240 μin Ni. The components are soldered to the nickel layer, and it creates a barrier over the copper. Necessary protection during the storage is provided by the gold. The gold also offers low contact resistance that is required by thin deposits of gold. This is one of the most widely used finishes in the PCB industry due to its compliance with RoHS regulations.

We can provide the printed circuit boards in various sizes, from small to large. The maximum panel size offered is 18″x24″, whereas board thicknesses can easily vary from 0.5mm~3.0mm (0.02″~0.12″). The outlines are created by methods such as routing, V-cut, and punching. We use laser equipment that helps us achieve finish thickness as small as 0.2mm (flex), and 1.0mm.

Every printed circuit board depends on the copper for carrying electricity. We understand that copper thickness plays a key role in the performance of these circuit boards. Thus, we allow the customers to choose from a variety of copper thicknesses, including 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ, up to 6 OZ. The solder mask helps in improving the aesthetic appeal of the components on the PCB. We can provide rigid flex printed circuit boards in various solder mask colors, including white, black, blue, green, red, and Taiyo PSR4000 white. The PCB can be availed in silkscreen colors – black and white.

rigid flex printed circuit boards have minimal space requirements that are optimized by 3D application. These circuit boards require no cables or connectors between the rigid parts. This helps reduce the board size, as well as overall system weight. These lesser solder joints also help assure high connectivity. Additionally, these boards have ZIF contacts that are integrated. These contacts help simplify the system interfacing. This 4 layer rigid flex PCB and other printed circuit boards are vacuum packed during the transit. This helps us assure the quality, as well as working condition of the boards.

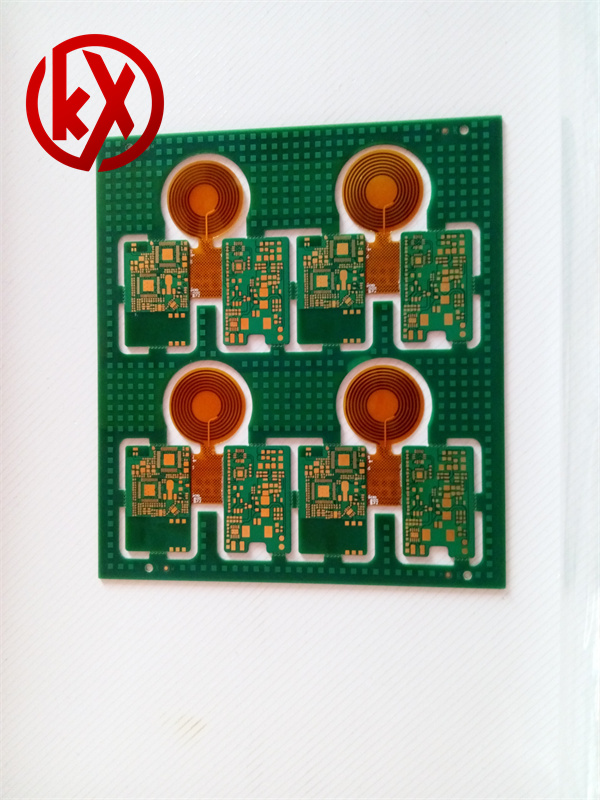

KXPCB provides rigid flex printed circuit boards in various standard and custom specifications. These printed circuit boards are used regularly in industries such as power, automobile, telecommunication and lighting. KXPCB's six-layered rigid flex printed circuit boards have gained popularity over the years. These printed circuit boards are known to offer flexibility, as well as design freedom to PCB engineers.

A six-layered rigid flex circuit board comprises 6 conductive layers, and are fabricated in a variety of sizes up to 18″ x 24″, and in board thicknesses 0.5mm~3.0mm (0.02″~0.12″). The outlines are created using methods such as punching, routing, and V-cut. We employ only laser drilling to create holes, which enables us achieve holes as small as 0.004″, and minimum finish thickness 0.3mm (flex), 1.6mm.

The conductive layers of this PCB are created using copper. We use various types of copper to meet the diverse application needs. Annealed copper is mostly used in applications that demand repeated movement of the printed circuit board. The circuit boards can be availed in various thicknesses ranging from 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ, up to 6 OZ.

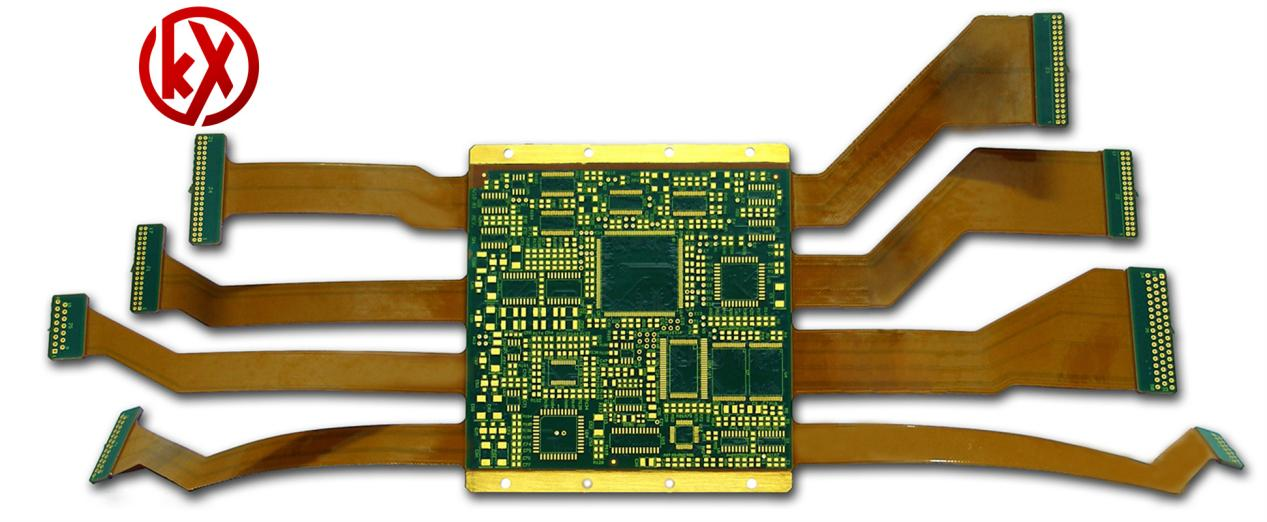

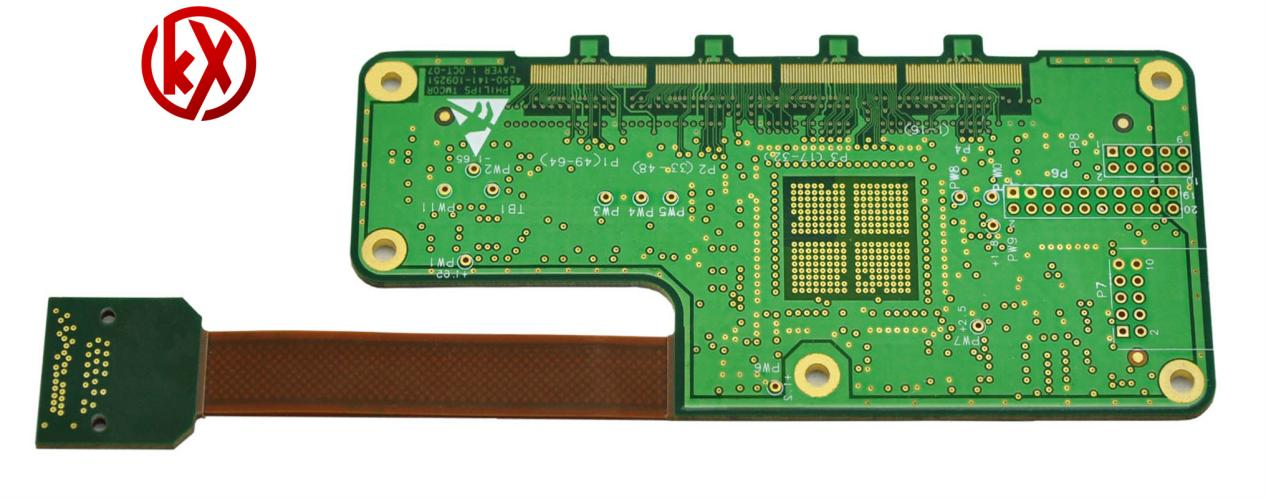

Rigid flex printed circuit boards combine rigid and flexible pcb board technologies, and are known for their operational efficiency. KXPCBprovides a wide range of rigid flex printed circuit boards that are regularly used by manufacturers, who manufacture transformers, inductors, stepper motors, planar magnetics, etc. We provide 8 layer rigid flex circuit boards, which are used in various industrial, as well as consumer electronic applications. These circuit boards comprise alternate layers of flexible and rigid circuits that combine the best of both technologies.

The printed circuit board is manufactured using polyimide and FR4 material. This combination helps improve the thermal stability of the board, as well as makes it ideal for high-temperature applications. Additionally, the variety of surface finishing options such as immersion gold, OSP, and HASL, helps improve the performance of these PCBs in challenging conditions involving UV and radiations, oils, and harsh chemicals. The PCBs can be availed in either of two solder mask colors – black, and white.

We, at KXPCB, can work on specifications, which are complex, as well as challenging. For instance, this 8 layer rigid flex circuit board can be availed in board thicknesses ranging from 0.5mm~3.0mm (0.02″~0.12″), and copper thicknesses 0.5 OZ, 1.0 OZ, 2.0 OZ, 3.0 OZ, up to 6 OZ. Also, we can assure the finish thickness of 0.2mm (flex), 1.6mm.

We employ fabrication methods such as scoring and break away routing, as well as punching and V-cut to create precise outlines. Our advanced laser drilling equipment enable us to provide drilled holes in sizes as small as 0.004″. Laser technology is also employed during the trimming and routing processes. Our advanced technology capabilities enable us to achieve the panel sizes up to 18″ x 24″, and various other complex dimensions.

All the printed circuit boards designed by us undergo rigorous testing before leaving the premises. These boards are considered ideal for applications, where space and weight can be a major concern. We have often concentrated on building circuit boards with lesser cables, connectors, and solder joints, while meeting a major requirement – a lightweight circuit board. This 8 layer rigid flex printed circuit board is vacuum packed that helps avoid shocks during transport, and, aids us to stay true to our quality commitment. In addition to this 8 layer circuit board, we can provide these rigid flex PCBs in any number of layers between 1 and 20. We can provide these printed circuit boards in a variety of layouts to meet the requirements of customers across various industries.

We constantly seek to improve our technology to provide you with the best prices, with continuous evolution in quality and agility in production.

We are very concerned with all environmental sustainability guidelines, thus correctly treating all waste and disposal in partnerships with certified companies, moving towards excellence when we talk about environmental management.

We have several promotional actions, aiming to meet your needs, whether related to urgent deadlines, low cost, or Rigid-flexible prototypes for testing.

There is now an abundance of printed circuit board manufacturers on the market. However, if you are looking for a supplier with many years of experience and expertise in Rigid-flexible production, you are spot on with us.

Besides the first class machines we used for our production line, We have a professional engineer and technical team, who can give you valuable suggestions on your design to help you to improve the reliability of the products and decrease your manufacturing cost.

Whether you want the bard board or assembled circuit boards – you are definitely not wrong with our innovative solutions and products.

As a printed circuit board manufacturer, we know very well that the requirements for Rigid-flexible boards are getting higher and higher, regardless of the intended use. Be it in the fields of medicine and the automotive industry or in artificial intelligence – a reliable PCB circuit board from our range is always used because it is designed for long-term use.

We became one of the leading printed circuit board manufacturers because we are not satisfied with mediocrity in the manufacture and PCB assembly of SMD printed circuit boards and have been relying on high quality since our foundation.

No matter what type of PCB you are looking for – you are guaranteed to find the right offer from the circuit board manufacturer

Over the years we have also received numerous certificates that confirm the high quality of our products and of which we, as a printed circuit board supplier, are particularly proud. This includes the certificate for the quality management system ISO 9001 and the certification for the environmental management system ISO 14001.

In particular, concern for the environment is very important to us, since circuit board manufacturers like us work with different chemicals.

We stand for reliability and the highest quality. In order to be able to guarantee this claim for each of our boards, our products go through a strictly controlled, environmentally conscious quality process.

Material selection – only high quality certified base materials reach our warehouse.

Tests – We have two AOIs and four highly flexible flying probe testers for optical and electrical tests.

Quality assurance – daily quality statistics as the basis for early error detection and preventive process management round off our concept within the framework of ISO 9001/2015 and ISO 14001/2015.