Time:2024-07-08 Preview:202

ALUMINIUM PCB MANUFACTURING PROCESS

What kind of field you can use for the Alu /Aluminum PCB

FR4 VS ALUMINUM PCB

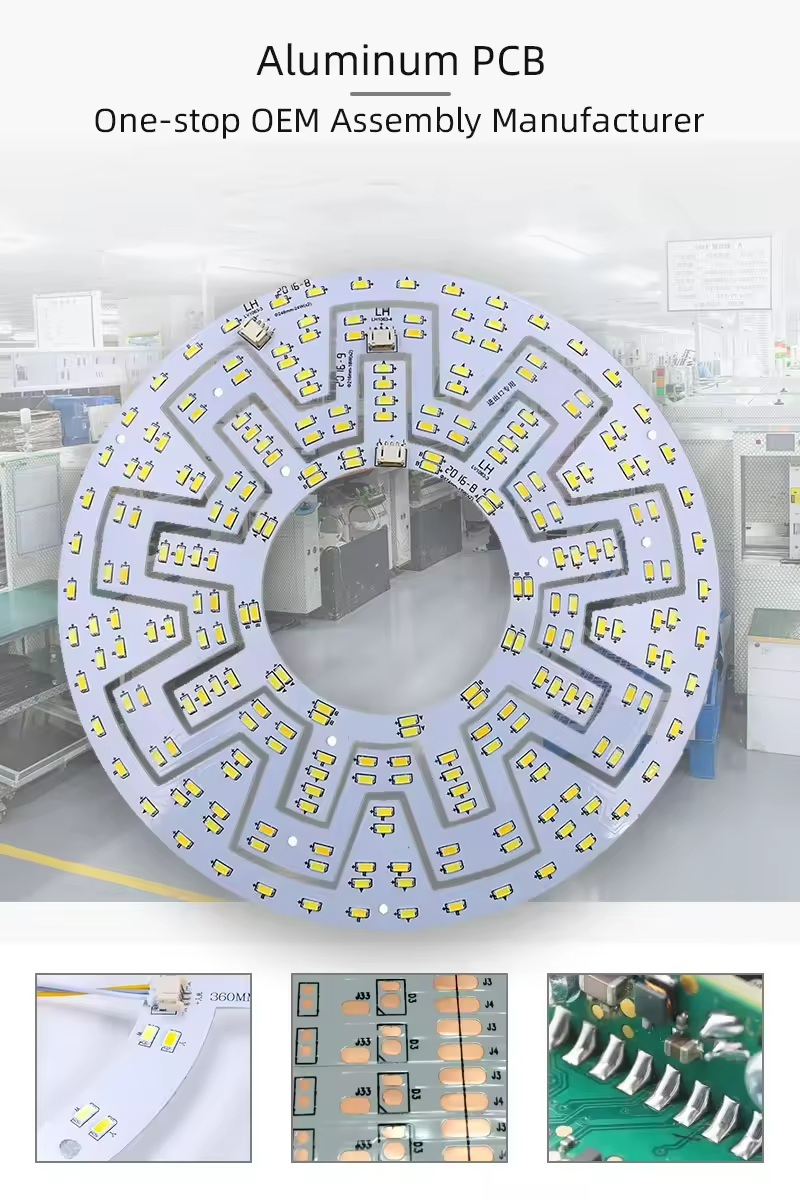

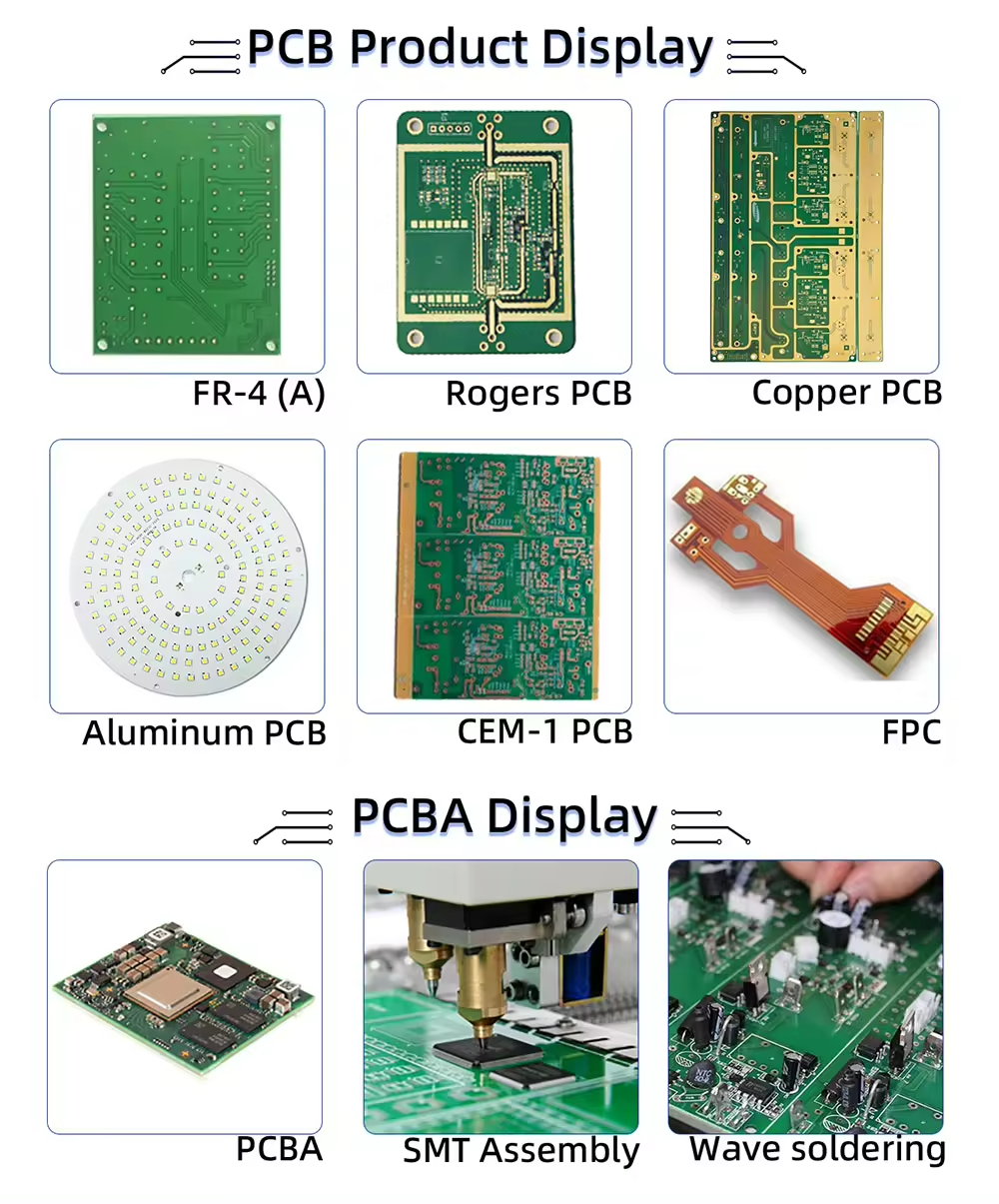

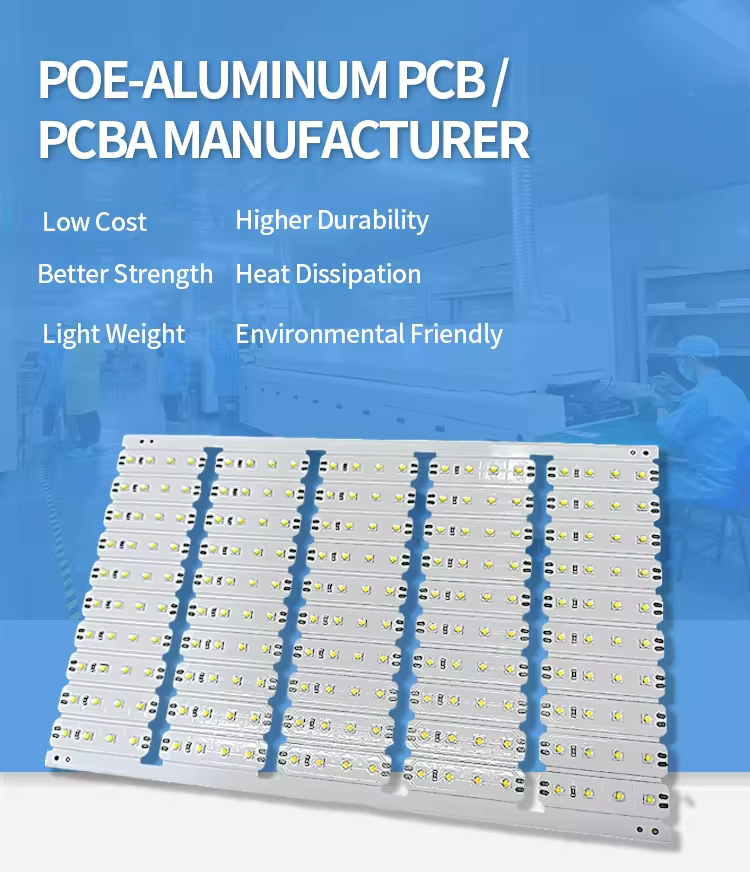

As a professional and reliable supplier with more than ten years of expertise in the manufacturing of Aluminum printed circuit boards, KXPCB can manufacture single-layer Alu PCB and 2 Layer / double sided Aluminum PCB. We are able to supply you with small, medium, or mass production at a reasonable cost on Aluminum PCB, and quality is always the key essential for us FX PCB passed the ISO9001 and the manufacturing process will strictly follow the quality control.

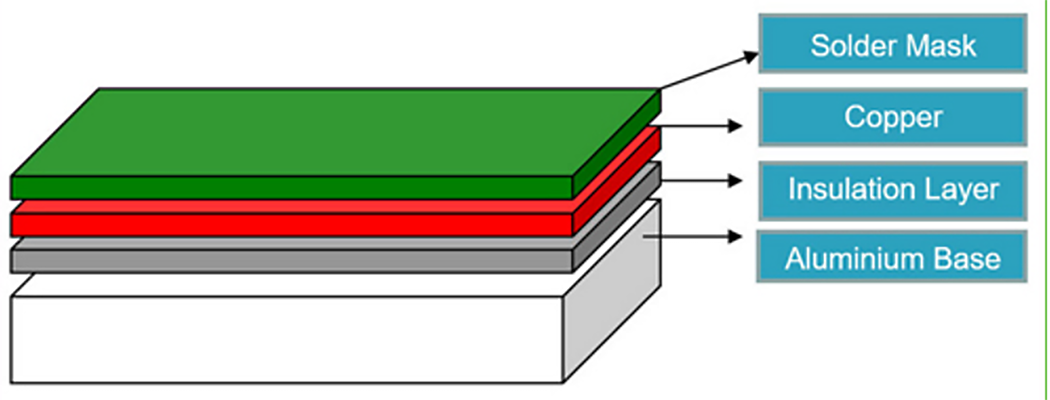

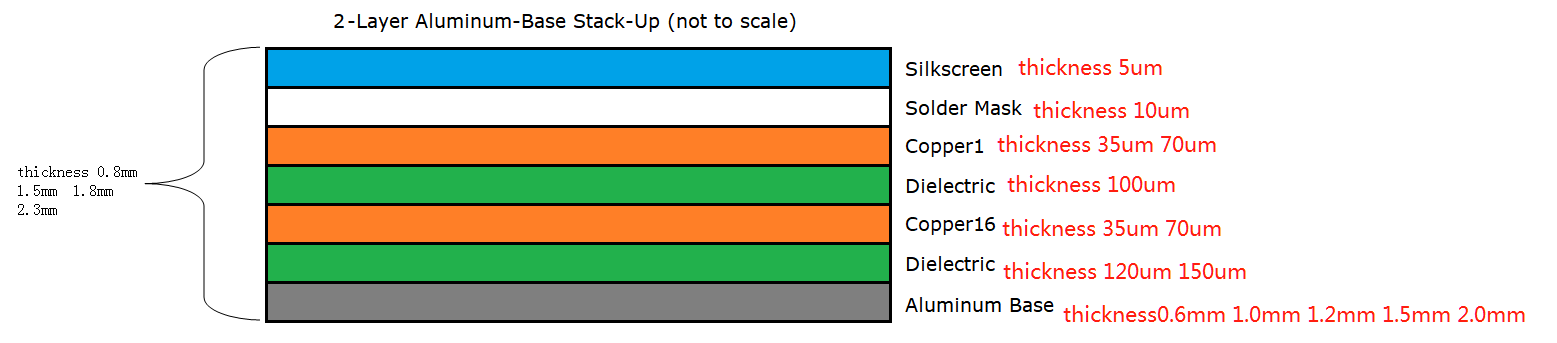

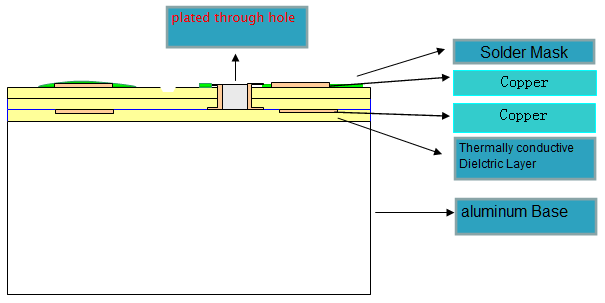

The aluminum PCB substrate is a metal-based copper-clad laminate with a good heat dissipation function. The single-layer Alu PCB is composed of a three-layer structure: circuit layer (copper foil), insulating layer, and metal base layer, see below stack up for your reference

We also designed a 2 Layer Aluminum PCB and multilayer Alu PCB for the high-end usage

No. | Item | Process Capability Parameter |

1 | Base Material | Aluminum core |

2 | Number of Layers | 1 Layer, 2 Layers, 4 Layers |

3 | PCB Size | 1 Layer & 2 Layers:1200*300mm or 600*500mm Multi-layers: 600*500mm |

4 | Quality Grade | Standard IPC 2 |

5 | Thermal Conductivity (ω/m-k) | 1W, 2W, 3W, 8W, 12W |

6 | Board Thickness | 0.8-6mm |

7 | Min Tracing/Spacing | 4mil / 4mil |

8 | Plated Through-hole size | ≥0.2mm |

9 | Non-Plated Through-hole size | ≥0.8mm |

10 | Copper Thickness | 1oz, 2oz, 3oz, 4oz, 5oz |

11 | Solder Mask | Green, Red, Yellow, White, Black, Blue, Purple, Matte Green, Matte Black, None |

12 | Surface Finish | HASL with lead, HASL lead free, Immersion Gold, OSP, Hard Gold, ENEPIG, Immersion Silver, None |

13 | Other Options | Countersinks, Castellated Holes, Custom Stackup and so on. |

14 | Certification | ISO9001, UL |

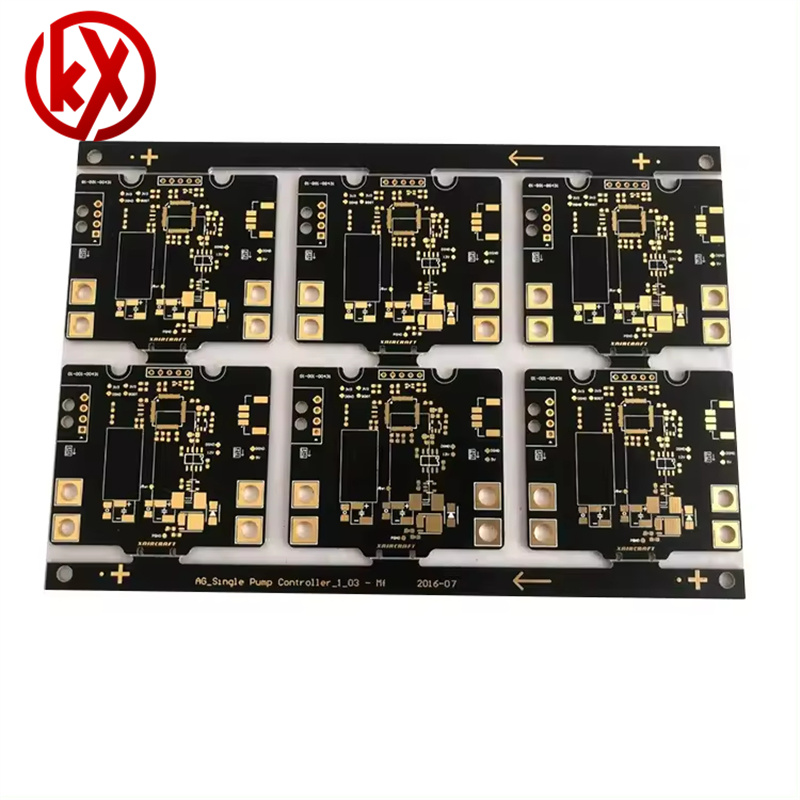

Copper PCB Capabilities

No. | Item | Process Capability Parameter |

1 | Base Material | Copper Core |

2 | Number of Layers | 1 Layer, 2 Layers, 4 Layers |

3 | PCB Size | 1 Layer & 2 Layers:1200*300mm or 600*500mm Multi-layers: 600*500mm |

4 | Quality Grade | Standard IPC 2 |

5 | Thermal Conductivity (ω/m-k) | 2W, 3W, 8W, 12W |

6 | Board Thickness | 0.8-2.0mm |

7 | Min Tracing/Spacing | 4mil / 4mil |

8 | Plated Through-hole size | ≥0.2mm |

9 | Non-Plated Through-hole size | ≥0.8mm |

10 | Copper Thickness | 1oz, 2oz, 3oz, 4oz, 5oz |

11 | Solder Mask | Green, Red, Yellow, White, Black, Blue, Purple, Matte Green, Matte Black, None |

12 | Surface Finish | Immersion Gold, OSP, Hard Gold, ENEPIG, Immersion Silver, None |

13 | Other Options | Countersinks, Castellated Holes, Custom Stackup and so on. |

14 | Certification | ISO9001, UL |

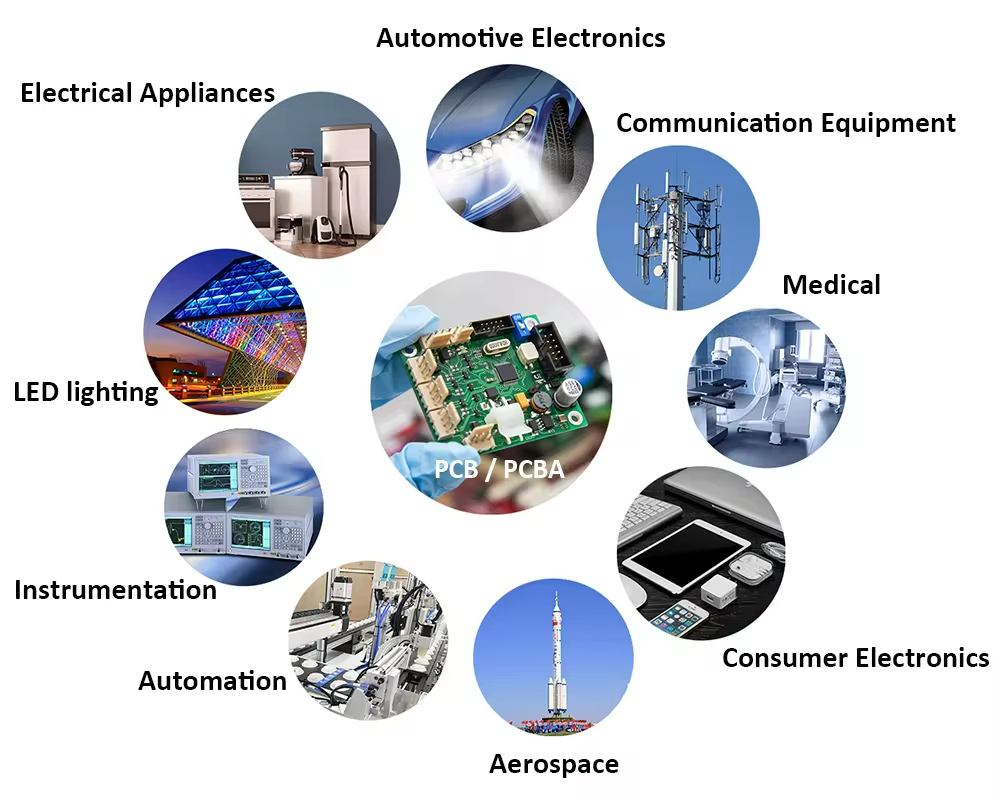

What kind of field you can use for the Alu /Aluminum PCB

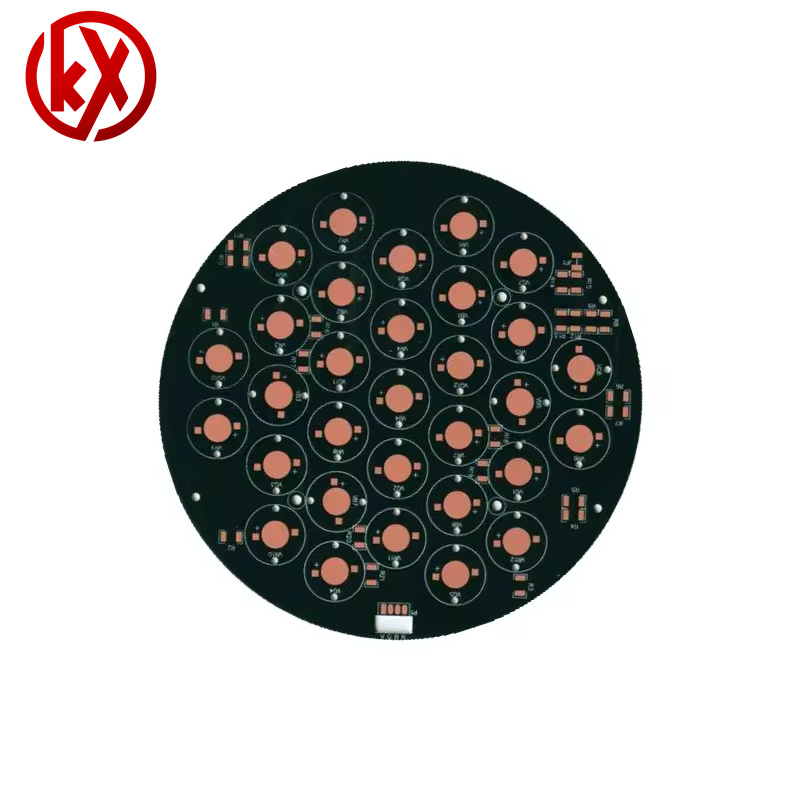

1. LED: It needs to use the Aluminum PCB Led board for Different kinds of LED and Lamps

2. Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, pre-amplifiers, power amplifiers, etc.

3. Power supply: Switching regulators, DC/AC converters, SW regulators, etc.

4. Communication electronic equipment: The high-frequency amplifier `filtering appliance` transmission circuit.

5. Automation equipment: Motor drivers, etc.

6. Automotive: Electronic regulator, igniter, power controller,

7. Computer: CPU board, floppy disk drive, power supply unit, etc.

8. Power module

9. Inverter, solid-state relay, rectifier bridge, etc

The most popular metal core PCB is one with an aluminum core. Nowadays, aluminum PCB vs fr4 is the more popular variety. What distinguishes aluminum PCB from fr4 then?

Price

A relatively conventional board material is FR-4 PCB. His cost is hence not high. Aluminum PCB cost vs. Fr4 is slightly more expensive.

Conductivity of heat

Compared to FR4, aluminum PCB offers superior thermal conductivity. Thus, aluminum PCB is preferred by producers of led lighting.

Applications

More FR-4 PCBs are used than aluminum PCBs. Because FR-4 is a conventional material that is also reasonably priced. Manufacturers prefer it as a result. The only industries that will use pricey aluminum substrates are those that demand great thermal performance.

· Aluminum PCBs are a great option for applications involving high temperatures and long operating times due to the high level of heat dissipation they offer.

· Another advantage of aluminum’s effectiveness and economy is its low price. Aluminum is a widely used metal that is inexpensive to mine and process. It is also widely accessible.

· Because aluminum is non-toxic, it is safe for the environment and a great material for uses including product recycling.

· Compared to fiberglass and ceramic materials, aluminum-based products offer substantially higher levels of strength and durability.

· Compared to other metals, aluminum is a particularly strong and sturdy substance that can withstand higher strain and stress during manufacturing and material handling.

· Aluminum is quite light. It increases the product’s strength and durability without increasing weight.

· When compared to old epoxy glass, the thermal conductivity of the utilized dielectric is 5 to 10 times higher.

· Thermal transfer is more dependable and efficient than conventional PCB.

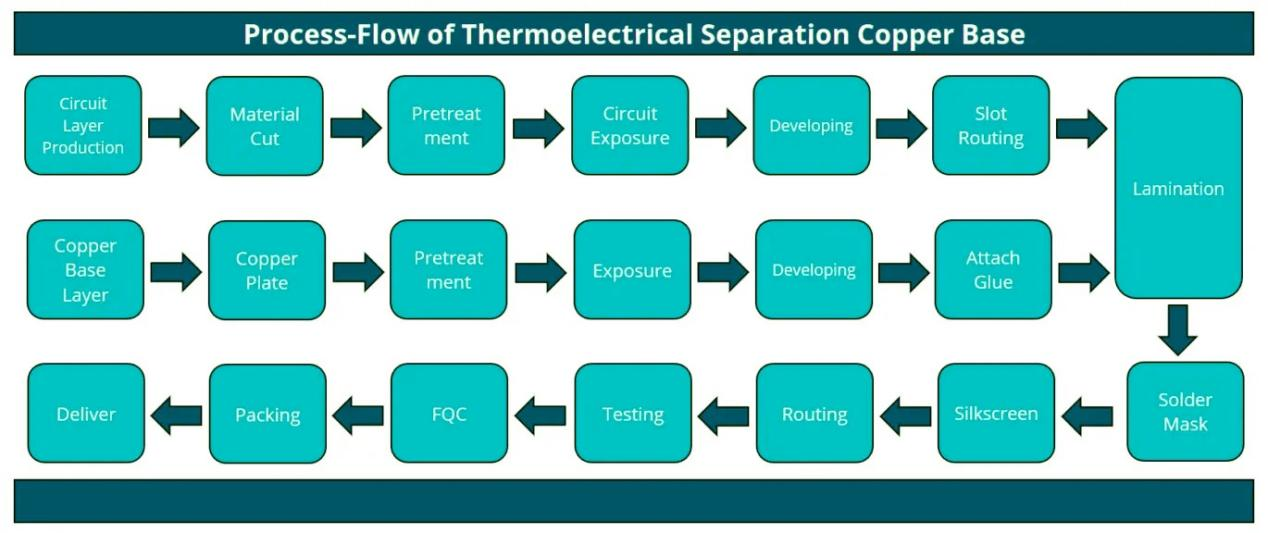

Most of the time, the same aluminum PCB manufacturing technique is used by all aluminum base PCB manufacturers. The degree of automation of their operations, the use of cutting-edge technology, and equipment are the only substantial differences between aluminum-based PCB producers.

Circuit boards made of aluminum

Aluminum PCB makers must take into account a few crucial factors in order to effectively produce any quantity of aluminum circuit boards.

Equipment for specialized imaging

For LED applications, a lot of aluminum-backed PCBs are required, and they are significantly longer than the production panels used in conventional aluminum PCB manufacture. Manufacturers of aluminum-based PCBs are required to have screen-printing equipment or specialized UV imaging equipment that is 60 inches wide.

Equipment for Specialized Scoring

Aluminum PCBs cannot be managed using the more widely used equipment available to obtain V-scores from conventional FR-4 materials. When possible, aluminum base PCB manufacturers can assist customers in designing the most affordable array to score panels.

Testing at In-Line High Voltage

Customers want to know whether the product they are purchasing has passed a voltage test, which is a distinctive need of PCBs. Withstanding voltage testing is a part of electrical test settings, which significantly lowers the cost to the customer.