Time:2024-02-28 Preview:112

Abstract: This article first describes the overview of the overall scheme of the circuit board assembly and welding automatic production line, comprehensively analyzes several common production line transportation schemes, analyzes the main characteristics of the circuit board assembly and welding, and designs a suitable overall production line transportation scheme and The key technologies in the process, and finally a summary of the processes related to the circuit board assembly and welding automatic production line proposed in this article.

Keywords: circuit board; assembly welding; automatic assembly; key technology

1. Introduction

Many main technologies in the automatic production of circuit board assembly and welding have many similar characteristics to the automatic assembly of some small parts. The results obtained can also be widely used in the automatic assembly of many other products. Moreover, the automatic assembly and welding production line has relatively soft and intelligent characteristics, which also pave the way for the application of automatic assembly lines in various fields, giving the production line greater advantages compared with other similar technologies. Therefore, studying the key parts technology of automatic production and assembly units of circuit board assembly and welding is of great significance to the manufacturing industry and has certain practical application value.

2 .Comprehensive description of the automatic production line in the circuit board assembly and welding process

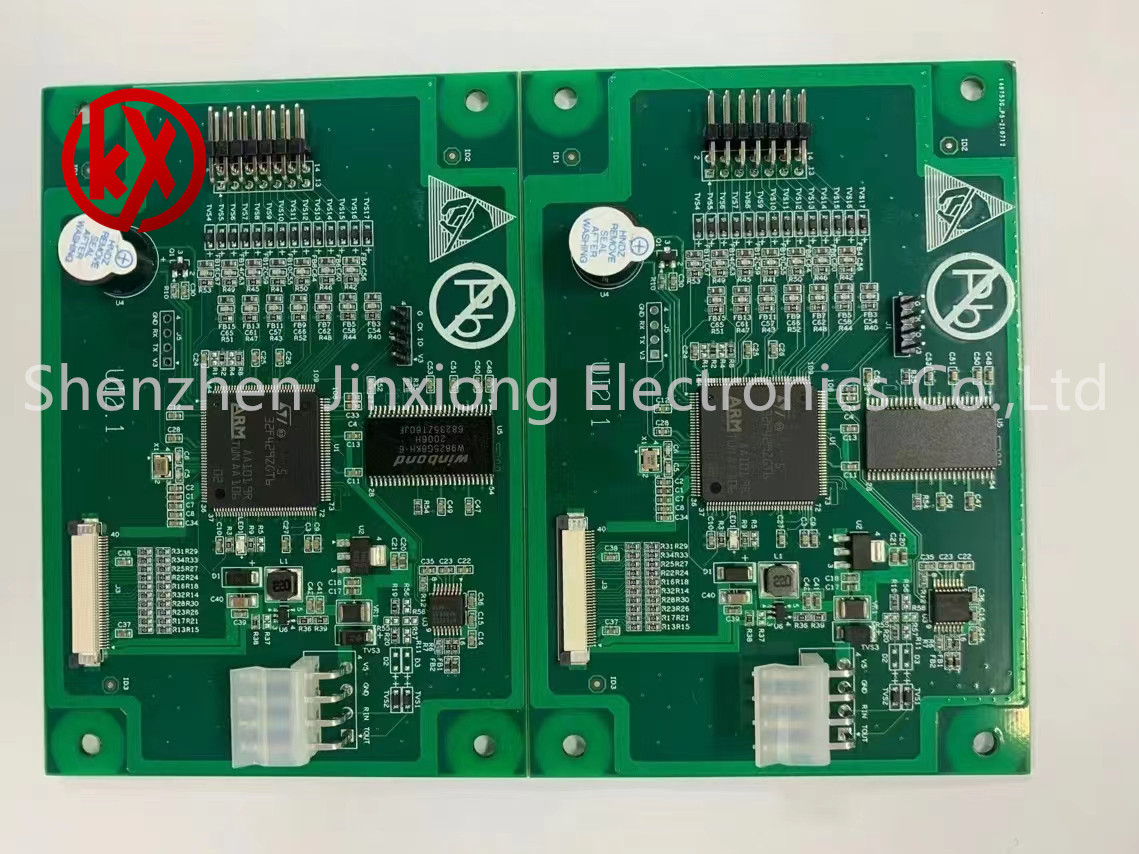

The circuit board assembly and welding automatic production line is a relatively complete automated assembly line, consisting of a moderate number of small parts, with relatively high precision and fast production speed. Mainly used in a series of operations such as welding and assembly of base shells and high-dielectric circuit boards. The product conveying process of the production line plays a great role in the overall efficiency. The structure, positioning method, assembly accuracy and efficiency of the assembly line, and many other operations are completed depending on the quality of the product conveying technology of the production line.